Njengomthombo wesine wamandla osetshenziswa kakhulu emkhakheni wezimboni, uhlelo lwe-compressor yomoya luhlobene eduze nokukhiqizwa. Ngaphezu kwalokho, i-air compressor system ngokwayo idla amandla amaningi ngenxa yezidingo zayo zokulawula iqoqo kanye nezidingo zokuphatha ukusetshenziswa kwamandla. Ukusabela enkambweni yohulumeni emhlabeni wonke abakhuthaza ngenkuthalo ukongiwa kwamandla kanye nentuthuko esimeme, kusetshenziswe ubuchwepheshe obuningi bokonga ugesi kanye nokwenza ngcono ukusebenza kahle kuma-compressor komoya ukunciphisa ukumosheka kwamandla.

Isistimu yokucindezela komoya ibhekisela ohlelweni lokuguqula amandla olucindezela umoya osemkhathini nge-compressor bese iwuhambisa endaweni lapho udingeka khona ngepayipi. Umgomo uwukucindezela igesi emkhathini wengcindezi ephansi ibe emoyeni onomfutho omkhulu ngokuzungezisa noma ukunyakaza okuphindaphindayo, bese uyihambisa endaweni lapho idingeka khona ngepayipi. Isihlungi sokungenisa umoya singakwazi ukuhlunga ukungcola nothuli emoyeni, ukuze umoya we-compressor uthole umoya ohlanzekile, ngaleyo ndlela uqinisekise izinga lomoya. I-cooler ingakhipha ukushisa okukhiqizwa i-compressor ngesikhathi sokusebenza, ngaleyo ndlela igweme ukushisa ngokweqile komshini. Isihlukanisi samafutha singahlukanisa umhwamuko kawoyela namafutha awuketshezi akhishwa i-compressor ukuqinisekisa ukuhlanzeka komoya. Ithangi lokugcina umoya lisetshenziselwa ukugcina umoya ocindezelwe yi-compressor ukuze unikezwe umsebenzisi uma kudingeka. Ipayipi lokusabalalisa umoya lihambisa umoya ethangini lokugcina umoya liwuyise ezintweni ezidingekayo zamandla omoya. Izingxenye zomoya zihlanganisa amasilinda, ama-actuator womoya, izingxenye zokulawula umoya, njll., ezingaguqula ukuphuma komoya onomfutho ophezulu we-compressor kube amandla emishini.

Ohlelweni lokuhlinzeka ngegesi, into eyisisekelo kakhulu yokulawula izinga lokugeleza, futhi umsebenzi oyisisekelo wesistimu yokuphakela igesi ukuhlangabezana nesidingo somsebenzisi sezinga lokugeleza. Kunobudlelwano obuthile phakathi kwesilinganiso sokugeleza esisheshayo kanye nokukhiqizwa kwegesi kwe-compressor yomoya. Ngokuvamile, uma izinga lokugeleza likhulu ngokushesha, ukukhiqizwa kwegesi kuyanda. Lokhu kungenxa yokuthi umthamo womoya owengeziwe okhishwa i-compressor yomoya ngesikhathi esinikeziwe, uyanda umthamo womoya ocindezelwe okhiqizwayo. Kodwa-ke, kufanele kuqashelwe ukuthi izinga lokugeleza okusheshayo kanye nokukhiqizwa kwegesi akuyona incwadi eyodwa kuya komunye, futhi kuthinteka isimo sokusebenza kanye nezimo zokulayisha ze-compressor emoyeni. Njengamanje, izindlela ezivamile zokulawula ukugeleza kwegesi zihlanganisa ukulayisha nokukhipha izindlela zokulawula ukunikezwa kwegesi nezindlela zokulawula isivinini. Kodwa-ke, njengoba i-compressor yomoya ayikwazi ukukhipha ukuthi kungenzeka ukusebenza isikhathi eside ngaphansi komthwalo ogcwele, okwamanje ngesikhathi sokuqala kusenkulu kakhulu, okuzothinta ukuzinza kwegridi yamandla kanye nokusebenza okuphephile kwezinye izinto zikagesi, futhi eziningi zazo ziwumsebenzi oqhubekayo. Njengoba i-motor yokudonsa ye-compressor yomoya evamile ngokwayo ayikwazi ukulungisa isivinini, akunakwenzeka ukusebenzisa ngokuqondile ukuguqulwa kwengcindezi noma izinga lokugeleza ukuze kuzuzwe ukufanisa amandla okukhiphayo okunciphisa ukuncishiswa kokunciphisa. I-motor ayivunyelwe ukuqala njalo, okuholela ekutheni injini isasebenza ngaphandle komthwalo lapho ukusetshenziswa kwegesi kukuncane, nokumosha okukhulu kwamandla kagesi.

Ngaphezu kwalokho, ukuthulula nokulayisha njalo kubangela ukucindezela kwayo yonke inethiwekhi yegesi ukuthi ishintshe njalo, futhi akunakwenzeka ukugcina ingcindezi yokusebenza njalo ukuze kwandiswe impilo yesevisi ye-compressor. Ezinye izindlela zokulungisa i-compressor yomoya (ezifana nokulungisa ama-valve noma ukulungisa ukuthulula, njll.) ngisho nalapho izinga lokugeleza elidingekayo lilincane, ngoba isivinini semoto sihlala singashintshiwe, amandla emoto ayancipha kancane uma kuqhathaniswa. Ngalesi sizathu, ngokuqapha ukugeleza ohlelweni lokuphakela amapayipi okucindezela umoya, i-Gongcai.com incoma i-Siargo Sixiang Insertion Mass Flow Meter – MFI, American Siargo MF5900 series gas flow meter.

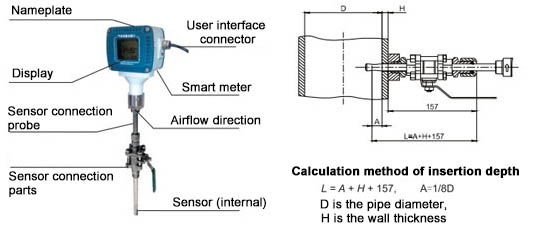

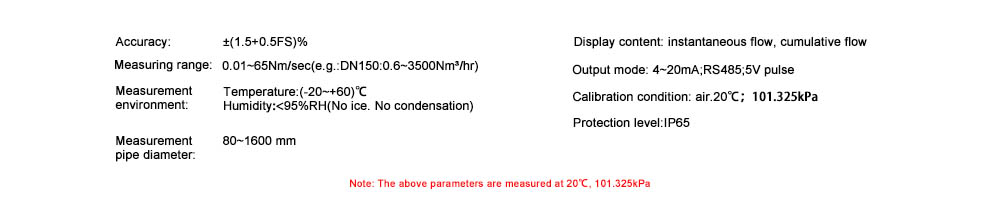

I-Siargo Insertion Mass Flow Meter - i-MFI yakhelwe ukuqapha nokulawula amapayipi amakhulu. Ukufakwa ku-inthanethi ngeke kube nzima futhi ukonga kakhulu. Imitha yokugeleza kwenqwaba yokufaka ifakwe i-valve yokuzivala, enikeza amakhasimende isisombululo esiphumelelayo sokulinganisa igesi ngokuphazanyiswa okuncane. Kunconywa ukuthi uyisebenzise kumapayipi anobubanzi obungu-≥150mm. Ukunemba kwawo wonke amamitha okugeleza kwesisindo sokufaka ngu-± (1.5 + 0.5FS)%, futhi angafinyelela amazinga aphezulu ngokuya ngezidingo zamakhasimende. Izinga lokushisa lendawo yokusebenza yalo mkhiqizo lingu-20—+60C, kanti ingcindezi yokusebenza ingu-1.5MPa. Lo mkhiqizo ungase futhi usetshenziselwe ukulinganisa nokulawula igesi ohlelweni lokukhiqiza, njengokuqapha nokulawula umoya-mpilo, i-nitrogen, i-helium, i-argon, umoya ocindezelwe namanye amagesi. Ngaphezu kwalokho, ingasetshenziswa kabanzi nakweminye imikhakha.

I-MFI Series Insertion Mass Flow Meter Product Parameters

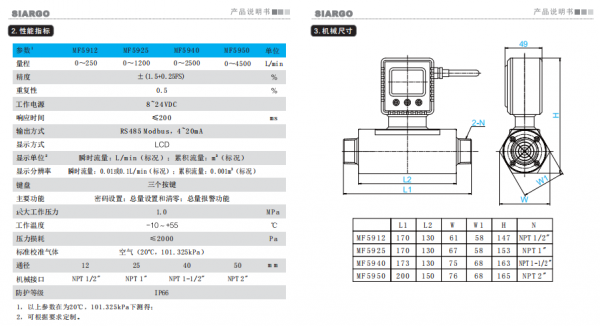

I-Siargo Flow Sensor - I-MF5900 Series imitha esekelwe kunethiwekhi eyakhiwe ngokusekelwe ku-chip ye-MEMS flow sensor chip yenkampani yethu. Le mitha ingasetshenziselwa ukuqapha ukugeleza kwegesi okuhlukahlukene, ukulinganisa nokulawula izinhlelo zokusebenza. I-MF5900 Series I-Gas Mass Flow Meter Reference Standard: IS014511; I-GB/T 20727-2006.

I-American Siargo flow sensor MF5900 amapharamitha wochungechunge:

Isikhathi sokuthumela: Jun-04-2024